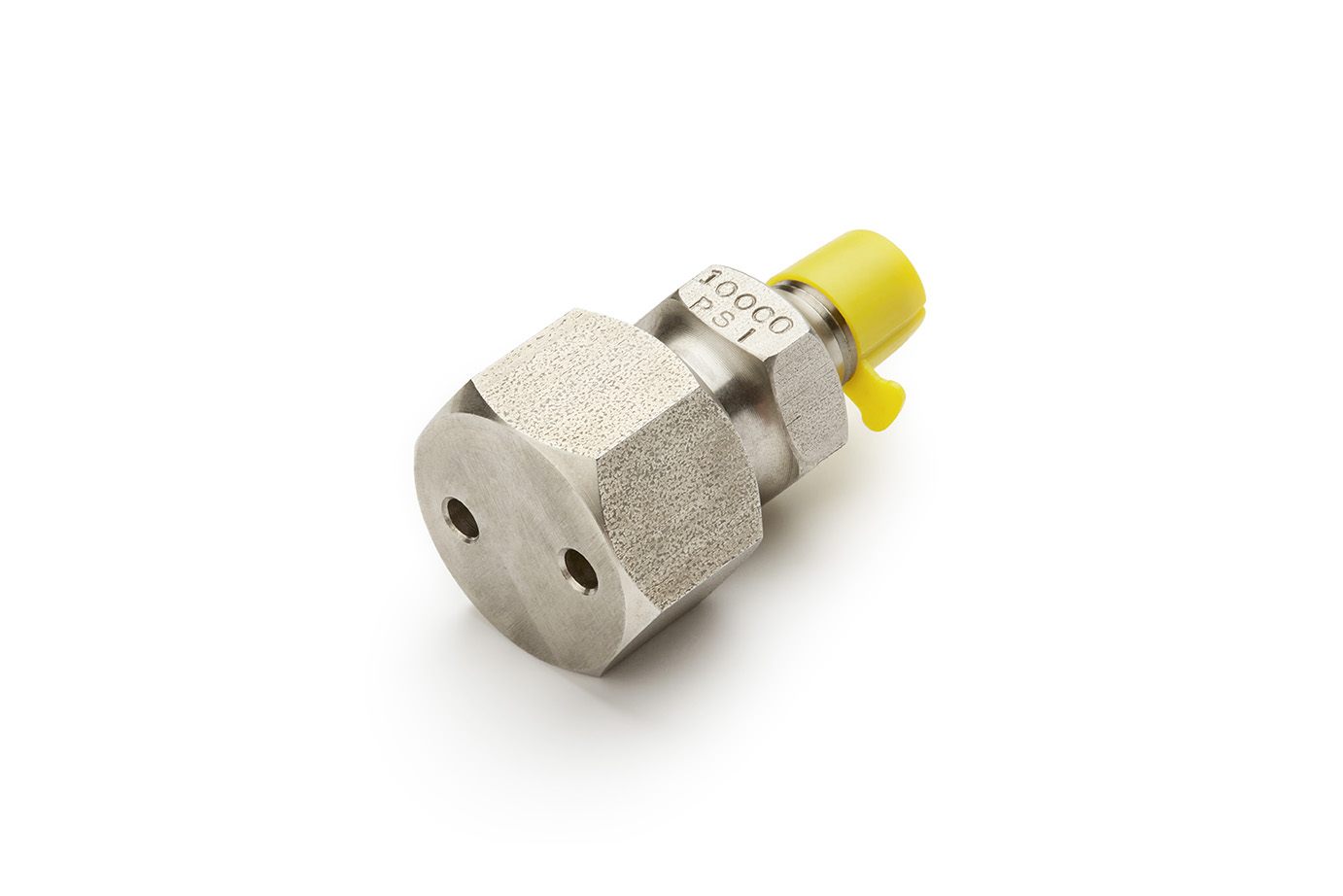

Easiflow Vented Cap

The philosophy behind the Easiflow Lubricant Injection Fitting with Vented Cap & all lubrication Injection fittings places great importance on the integrity of back seating (non return) capacity.

PREAMBLE

In cases where check valves within a valve body at lubricant injection points fail to back seat in service, the grease or lubricant fitting must seal under line pressures.

Furthermore, modern lubrication injection pumps are capable of generating 7,500 Psi. The new fitting is tested and rated to 10,000 PSI. Some other patented fittings in ¼” size do not rate to even 7,500 because of wall thicknesses between threads being less than Engineering Minimums.

The spring is tapered to ensure easy flow of lubricant outside and through the fitting, avoiding solid locking. The top loaded spring and ball retained by the pressed tee piece prevents blow out.

SPECIFICATION MATERIALS

PLUG, BODY & CAP 316 Stainless Steel

SPRING Tapered shape in Inconel 600

BALL Monel K500

O’RING Nitrile 70/90 D. Plus Teflon Backing Washer

TAPERED SPRING HOLDER 316 Stainless 2B finish

EASIFLOW ORIFICES Inlet 5MM Dia, Outlet 6MM Dia

THREADS Available ¼”, 3/8″, ½” NPT. Standard. Other threads available on request.

PRESSURE RATING 10,000 PSI.

SEALING Observe primary metal/metal seals of plug to body and ball to plug

Fire-safe

Secondary back-up seal by O-Ring

QUALITY ASSURANCE & MARKINGS: Basis of AS3902 (ISO 9002) full material certification. Marked with Grade, Pressure Rating, Quality Batch No. Quality batch number eg (BN 970203) will relate to Material Heat Certificates and Batch sample Stub Ends held at our factory in Australia, in this case batch number three produced in February 1997.

GAUGING & TESTING

All threads gauge tested. All fittings pressure tested, to 100 PSI bubble.

EASIFLOW CHARACTERISTICS

By increasing the outlet orifice size from the inlet orifice, lubricant and sealant flow is enhanced. By tapering the spring and holder, in the event of sealant hardening, i.e. if non PLI sealant were used, the wedge effect of the spring and retainer will assist with flushing and breakdown of a solidified mass. In the case of some fittings with parallel springs it is possible that the spring acts as an anchor reinforcement impeding complete dislodgment by flushing pressure.

VENTED CAP

The cone within the vented cap seals metal to metal on the inlet orifice taper.

ASSEMBLY

Ball location sealing point is polished on assembly by a controlled hammer peen. Plug is screwed into place and torqued with non-standard Hexagon Key and should not be removed. Each fitting is then pressure tested for thread and ball seal integrity.

SEALS

By incorporating primary seals of metal to metal design the fitting becomes “A Fire Safe Check Valve”. This can be seen on the drawing plug to body and ball to plug,

If unforseen field plug removal and replacement allows a hair or minute dirt particle onto the seat area plug to body, the secondary O-Ring Seal on the plug acts as a back-up only and seals the fitting when needed. Any disassembly must be noted, reported and the fitting tagged for replacement at the next maintenance or shut down. If necessary, the fitting may be returned to the factory for a new plug.

Product Enquiry

Thank you for your interest in Pressurelube. Please tell us about your needs and how we can help you. We will be back in touch with you shortly.