Pressurelube at the

forefront of innovation

Services

Short term

Valves are flushed with our liquid Valve Flush and then injected with Synthetic Valve Lubricant. This process maintains the valve and its sealing integrity.

Long term

The Pressurelube team will design a tailor-made preventative maintenance programme based on the customer’s needs according to their unique operating environment and frequency of valve operations.

Valve refurbishment and repair

Offering comprehensive valve repair and testing services on various types of valves including ball, gate, plug, and wellhead valves.

PLI vs Presentation SWID

In the oil & gas, petrochemical, mining and general process industries, valves are one of the most common mechanical devices on any pipe line, process plant, well head, oil & gas process rig or ship etc., and more than often are the most neglected piece of moving equipment. Usually very little attention is paid to them until it is time to operate the valve in a flow control, shut down or emergency situation.

PRESSURELUBE

Maintenance Products

We have developed a full range of specialised valve maintenance products for the oil and gas industry. Our LIQUID VALVE FLUSH is developed to remove even the most stubborn of hydrocarbon deposits and old hydrocarbon sealants from the seal and spring areas of a valve, without damaging elastomers or seals. It will also dissolve waxes produced in oil production, thus allowing the valves to be effectively flushed prior to lubrication and sealing. It is applied with an air operated liquid injection pump.

We developed our SYNTHETIC VALVE LUBRICANT to be used in continual P.M. systems as a cheaper alternative to costly sealants. PLI’s synthetic lubricant is resilient to all products coming up a production string or produced in a gas processing plant. This reduces the need to stock various types of lubricants and therefore reduces costs. Since it is fully synthetic it will also not harden or block up the injection ports reducing torque and giving a perfect seal even after repeated cycling. This lubricant can be used in ball gate and plug valves. For geothermal valves, you may use the specially formulated SYNTHETIC GEOTHERMAL LUBRICANT, a high temperature (up to 900F) lubricant, developed for geothermal use. Our updated 2008 products will also now resist condensate.

PLI’s SYNTHETIC VALVE SEALANT is a last line of defence in valve maintenance, i.e. a valve must be sealed at all costs to eliminate the need for an untimely shut down. Our valve sealant contains no PTFE-fillers, will not harden and is excellent for emergency seat renewal and low pressure sealing problems. It comes in various grades, but the standard grade is good for H²S and CO² services. The 2008 product will be immiscible in condensate.

PLI’s SELF-MOULD stick packing is used in stem packing glands on valves and packing boxes on pumps. It will mould to any shape and outlasts conventional packing considerably. It is also synthetic and has properties similar to our sealant.

PRESSURELUBE

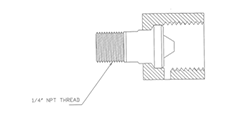

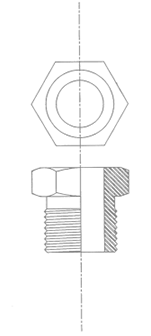

Fittings and Adaptors

With our 316 SS EASI FLOW VENT CAP LUBRICATION FITTING with Inconel 600 spring and monel K 500 ball the heaviest of sealants can be pumped and will flow freely due to the “EASI FLOW” concept. We also manufacture pressure relief tools and a full range of adaptors. Please consult the literature and drawings in the Fittings and Adaptors sections.

PRESSURELUBE

Pumps and Equipment

The HIGH PRESSURE AIR OPERATED LUBRICATION PUMP is designed to be the lightest and most mobile, but is still heavy duty enough for the oil and gas market’s toughest locations onshore or offshore. The pump system with 75:1 ratio air motor is capable of producing 7,500-psi lubricant/sealant pressure and has a flow rate that will thoroughly lubricate any valve. We also have an optional 140:1 ratio air motor for those higher-pressure applications that will product up to 14,000-psi lubrication pressure.

We have installed FIXED WELLHEAD LUBRICATION SYSTEMS where we installed a stationary pump with SS piping to a hose reel central to the wellhead deck area, enabling wellhead valves and diverter valves to be lubricated without the need to move equipment.

The PORTABLE 9649L BUCKET PUMP is a small unit developed to do those one off valve jobs where bigger pumps are not ideal or where an emergency occurs and a quick response with a helicopter is required. Our liquid injection air operated high volume mounted pump with stainless steel TANK TROLLY is designed to inject our liquid valve flush into valves. This unit can produce controllable injection pressures up to 10,000 psi, enabling the flush to cut the most stubborn of hardened materials.

Pressurelube can also make lubrication equipment to suit an individual customer’s needs and requirements. Some options we offer are skid mounted with compressors and mobile units mounted in 4 X 4 trucks for pipeline applications. In our range we can offer a Zone1 compressor unit, uniquely designed for complete safety in hazardous areas.